Plastic Welding FAQ

This page answers plastic welding frequently asked questions, including which materials can be welded? Where to get plastic welding tools serviced and repaired, where to get technical support and how you can view Weldy hot air tools.

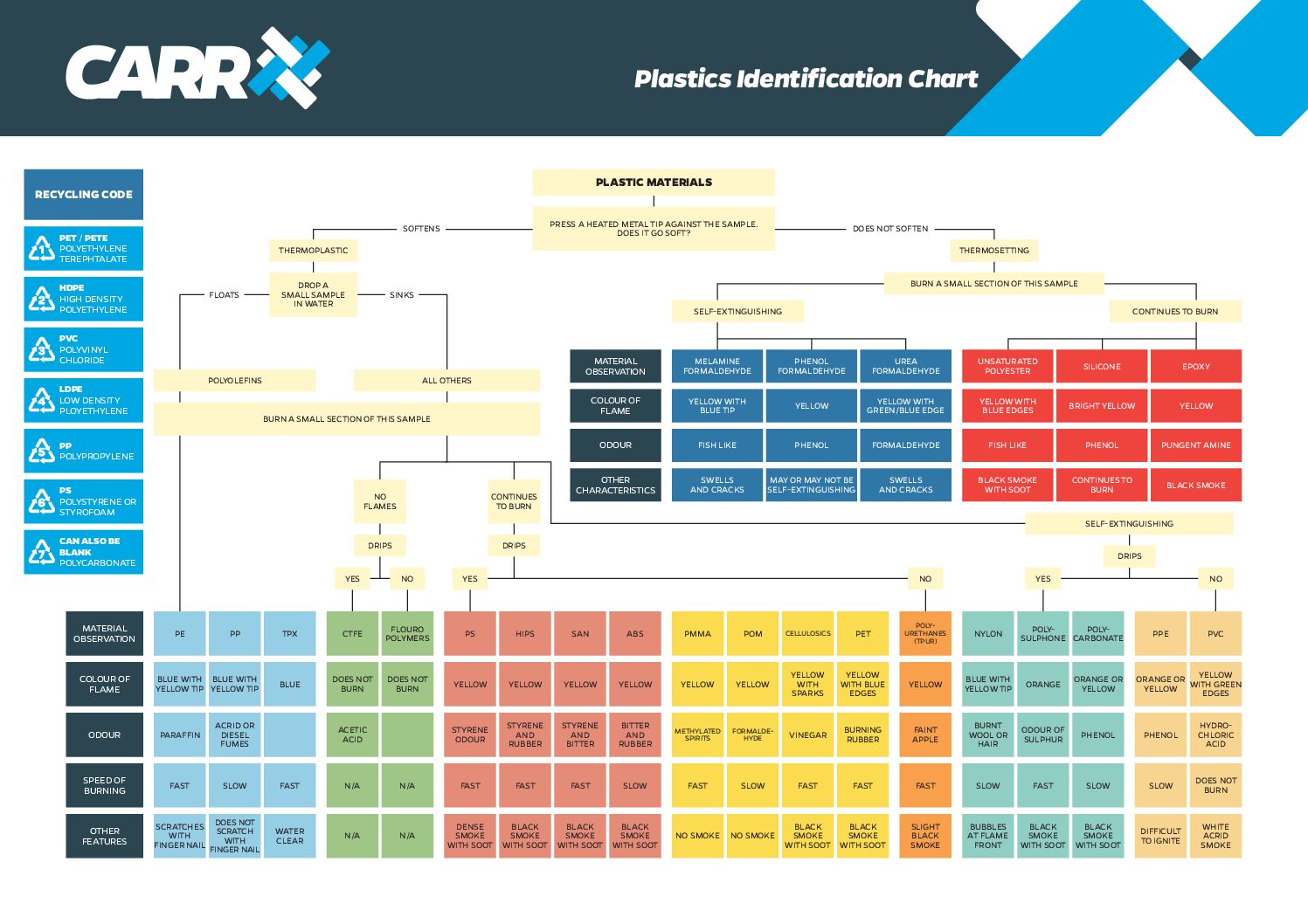

Only Thermoplastics can be welded. You must weld like-for-like plastic to achieve a structurally sound bond. Along with our plastic identification chart, CARR New Zealand offers plastic weld rod test packs containing a range of common plastics, these test packs can assist you in identifying which plastic you are working with.

| ABS: | General purpose ABS grade available in limited colours. Uses include motor cycle farings, appliances housing, and car parts |

| HMWPE: | Will weld both HMWPE and U-HMWPE sheets. Temperatures need to be very high and air flow a minimum for good adhesion and to minimize distortion |

| HDPE-C: | High Density Polyethylene (Crate grade) – UV stabilized, formulation for high speed welding a variety of injection moulded crates and bins. Available in a wide range of industry colours. |

| HDPE-PE100 | High Density Polyethylene (Pipe grade) – formulated for welding pipes, sheet or extruded and blow moulded products. |

| HDPE-S | High Density Polyethylene (Sheet Grade)- UV stabilized, formulation for high speed welding a variety of injection moulded crates and bins. Available in a wide range of industry colours. |

| MDPE-R: | Medium Density Polyethylene (Rotational grade) – UV stabilized formulated for welding tanks, bins, drums or products made by the rotational moulding process. Available in a full range of ‘Cotene’ tank colours |

| L-LDPE: | Linear Low Density Polyethylene – UV stabilized, a versatile blend of linear polyethylene plus adhesion promoter allowing it to adhere to all densities of polyethylene. Available In a wide range of colours – including motorcycle colours. |

| PP-C: | Polypropylene (Crate grade) – High impact copolymer for high speed welding of crates, bins and automotive parts. Has good sanding properties for car bumpers etc. Available In a wide range of industry colours for crates, motorcycles and car headlamp bodies |

| PP-S: | Polypropylene (Sheet grade) – For welding polypropylene sheet or extruded products – UV stabilised |

| PVC: | Rigid Polyvinyl Chloride (PVC) – Formulated for good ‘weldability’ ductility and sanding characteristics. Good acid resistance |

| PVC-F: | Flexible (soft) general purpose Polyvinyl Chloride (PVC) |

R = Round

d=2mm, 3mm, 4mm and 5mm

TS = Triangle S

w=3mm, 4mm, 5mm, 6mm and 7mm

TA = Triangle A

w=3mm, 4mm, 5mm, 6mm and 7mm

V – Triple

w=3mm, 4mm, 5mm, 6mm and 7mm

S = Strip

w=8mm, 13mm and 20mm

ST = Trilobal

w=6mm

Along with our instructional videos and technical data, we use a range of re-sellers across various industry sectors. Contact us for further advice, or visit us in our showroom at 6 Ra Ora Drive, East Tamaki, Auckland where we have a wide range of available tools on display.

Yes, we have an in-house service department and a broad range of spare parts and accessories on hand. Learn more.

Yes of course. Our staff are Leister trained and have experience across many industry sectors. Being the exclusive distributor for Leister and Weldy equipment in New Zealand and Pacific Islands, we have access to a database of technical support via the Leister extranet. The data has been developed over 70+ years of research and development.

Plastic Welding: How To

Which materials can be welded? Only Thermoplastics can be welded. You must weld like-for-like plastic to achieve a structurally sound bond. CARR New Zealand offers plastic weld rod test packs containing a range of common plastics, these test packs can assist you in identifying which plastic you are working with.

Step 1.

Prepare the weld surface. Ensure it is clean of dust and dirt so that you can achieve an unobstructed plastic-to-plastic bond. Notch out a “V” groove along the crack or join.

Step 2.

“Tacking” the join or crack together helps to secure the material in place to ensure there is stability and no misalignment of the joins. Run the tip of a tacking nozzle or heated metal item along the join to create an initial bond.

Step 3.

Using a speed welding nozzle or by free hand pendulum welding technique, introduce the plastic weld rod to the weld zone. Ensure equal levels of hot air are directed at the plastic weld rod and the weld surface to ensure they reach “plasticity” at the same time.

Step 4.

When the surface plastic shows signs of slight wetting, move the welding nozzle along the groove while at the same time applying downward pressure on the weld rod to ensure a sound bond.

The below video demonstrates extrusion welding and the capabilities it presents. Please talk to our team about the range of tools and equipment we have on offer.

Weldy Mini Welder Roof 2 Wedge Welder. Lightweight and easy to operate. Suitable for all pitched roofs, the miniwelder roof2 can be used for all PVC and TPO sub-roof membranes up to 1 mm. As the welding wedge technology manages without air having to be blasted, the sub-roof membrane does not flap about during the welding process. Don’t waste your money on toxic solvent welding agents.

WELDY pitched roof welding with miniwelder roof2

The WELDY miniwelder geo2 is the perfect professional lightweight welder for various geomembranes. The handy hot wedge welder prevails giant machines in welding quality: handy, simple and good! Perfect welding seam with a compact wedge welder of only 4.0 kg! Yes, only 4 kg.

- Lightweight and compact

- Closed loop control of temperature and drive

- Easy and user friendly

- Constant speed on vertical and variable road load

- Wide engineering projects as expressways, reservoirs, waterproofing works

- For LDPE, PVC, HDPE, EVA, PP

- Free adjustable speed up to 7.2 m/min

- Welding temperature up to 480°C

- Stable performance against ambient temperature and voltage fluctuation

WELDY miniwelder geo2 for geomembranes

Professional welding tools for overlap and seam welds, designed for easy use in the tarpaulins and billboards industries.